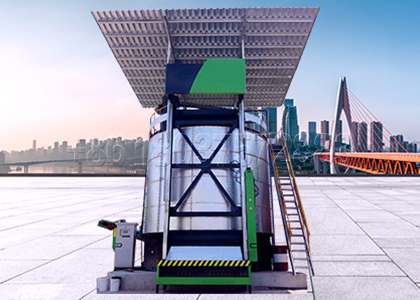

Fermentation vessels for sale

In vessel composting equipment can be used for the treatment of pig manure, chicken manure, cattle manure, sleep manure, mushroom waste, Chinese medicine waste, crop straw and other organic waste, and only need less time to complete the harmless treatment process. It has the advantages of covering less (fermentation tank machine only covers an area of 10 -30 square meters), no pollution (closed fermentation), completely killing the pest eggs, so it is the best choice to realize the resource utilization of waste materials for quaculture enterprises, circular agriculture, ecological agriculture.

In addition, according to customer requirements, we can customize 5-150 cubic meters different capacity and different forms of fermentation tank. In the process of fermentation, aeration, temperature controlling, agitation and deodorization can be controlled automatically. The pneumatic discharging device can discharge the material quickly. The whole process is controlled automatically without the operation of the workers.

In vessel composting equipment refers to a group of methods that confine the composting materials within a building, container or vessel. In-vessel methods rely on a variety of forced aeration and mechanical turning techniques to accelerate the composting process. Many methods combine techniques from the windrow and aerated pile methods in an attempt to overcome the deficiencies and exploit the attributes of each method.

Main technical parameters of fermentation machine

| Modle | Heating Power (kw) | Stirring Power (kw) | Reducer Model | Stirring Speeding (r/min) | Overall Size (mm) |

|---|---|---|---|---|---|

| FJD-10 | 4*6 | 11 | BLED84-493-11 | 3 | 2400*2400*6900 |

| FJG-20 | 8*6 | 18.5 | BLED95-391-18.5 | 3 | 3700*3700*8500 |

2 ways to ferment manure for producing organic fertilizer

During the process of organic fertilizer fermentation, there are two methods to use in ferment industry. It is suitable for you to make a compost or using our bio organic fertilizer fermenter. Meanwhile, it can help you build green ecological agriculture.

Organic fertilizer fermentation pot for sale

How to ferment organic matter or manure into organic fertilizer by using aerobic fermentation pot? The equipment takes advantage of the decomposition of microorganisms activity. In vessel composting equipment uses aerobic microorganism activity through continuous aerobic fermentation in a closed ferment. Then decomposes the organic matter and material at high temperature. Thoroughly deodorizing and killing parasites, germs and other harmful substances, the moisture content of the material decreased, the volume decreased. Finally it produces a large amount of organic fertilizer rich in organic matter. How do you think about aerobic fermentation pot? Please send an fermentation tank quotation to us, we will offer price sheet to you as soon as quickly.

Fertilizer compost turner for fermentation

To make manure convert to organic fertilizer, organic fertilizer compost turner machine is another method to produce fertilizer. Compared with aerobic fermentation pot, the fermentation period is longer, abut 10 -20 days. It can help you ferment fertilizer by turning materials regularly. There are mainly two kinds to choose, groove type composting, windrow composting. But both of them belong to the ground pile fermentation mode. And the material is stirred and crushed at regular intervals by the turning machine. The decomposition of organic matter will be under aerobic condition. It also has a broken function, which greatly saves time and labor force. At the same time, it makes the production efficiency and product quality of the organic fertilizer plant improved significantly and the cost reduced greatly.

Several advantages of using in vessel composting equipment

- High temperature fermentation of biological bacteria, low operating cost is available.

- Fermentation tank design adopts insulation design which can prompt high temperature fermentation completely. The large fermentation tanks can easily digest the pest eggs. The temperature can reach above 50 degree in fermentation room. By this design, it can maintain more than 7 days which can better kill eggs, pathogens and weed seeds completely.

- Add biological deodorization equipment, no secondary pollution. It is good for ecological environment.

- Structure of body adopts stainless steel materials which can have long service life. Meanwhile, it can reduce the maintenance cost. Then help you make a lot of benefits.

- The advantages of covering less (fermentation tank only covers an area of 10-30 square meters), can help you save a lot of space to produce organic fertilizer.

- The whole system adopts electric automatic system and reduces massive labor cost. And compared with compost machine, the organic fertilizer output of fermentation pot is more large. How do you think about it?

What is the necessity of industrial machine of fermentation process in production of organic fertilizer?

Traditional fermentation method needs take long period and much space to make animal manure into organic fertilizer. During the management, it costs a lot of labors and times to turn compost. Finally, adding other nutrients to the compost can not be nixed evenly. Therefore, using industrial fermentation tanks to making organic fertilizer is necessary for farmers and industrial factory.

At first, stirring function in material conditioning. In the process of fertilizer production, it is available to add all kinds of auxiliary materials to adjust the carbon-nitrogen ratio, ph and moisture content. Then, mix all the materials together roughly in proportion by industrial fermentation equipment. Finally, it can achieve the purpose of prompting high quality organic fertilizer.

Secondly, adjusting the temperature( can be adjust to 80-110 degree) to kill the pest eggs completely. Meanwhile it reduces the period to make organic fertilizer. In the process of fermentation, the raw material are fully contacted and mixed with air. A large amount of fresh air can be preserved in the material heap. After all, it is conductive to the active generation of fermentation heat by aerobic microorganisms and the high temperature ride of the heap.

Thirdly, improving the permeability of the raw material pile. The fermentation compost machine can process the material into small lumps, making the thick and dense pile fluffy and elastic, and forming the appropriate porosity.

Finally, adjusting the moisture content of the raw material pile. The suitable moisture content of raw fermentation is below 55, the standard of finished organic fertilizer is below 20. during fermentation, the biochemical reaction will generate new water. The consumption of raw materials microorganisms will cause the water to lose its carrier and become free.

How does in vessel composting equipment work?

Compared with anaerobic, continuous fermenting tank machine belongs to aerobic fermentation. Aerobic fermentation is critical for you to produce organic fertilizer with quality. Therefore, you should reasonably control conditions for fermentation. What is more, our organic compost pot is designed for converting manure to fertilizer according to principle of aerobic composting. And it belongs to a kind of fully automatic fermentation equipment. Animal manure enters fermentation tank from the upper part, and the sensors can automatically senses temperature and oxygen content, so as to provide a favorable condition or microorganism activity in manure. And the air supply system can send air into the fermentation tank. When it finishes fermentation, you can collect organic fertilizer.